Planet

People

back to top

Goal 2020

Realization 2020

Goal 2021

Goal towards 2025

We build strong partnerships to work together towards a circular supply chain, in turn contributing to a circular economy

EPS: continue pilots, develop concrete and commercial business services

LPR: start pilots in Italy and Portugal, develop business case for traceability

EPS: smart tracking concrete services, pilots to monitor quality of fresh produce during transport

LPR: pilots in the UK and Germany continued to enhance traceability

Continuing to develop and to roll out the business case for supply chain analytics and smart trays

Material

topic

Pro-active collaboration

with stakeholders

Partners

Goal 2020

Realization 2020

Goal 2021

Goal towards 2025

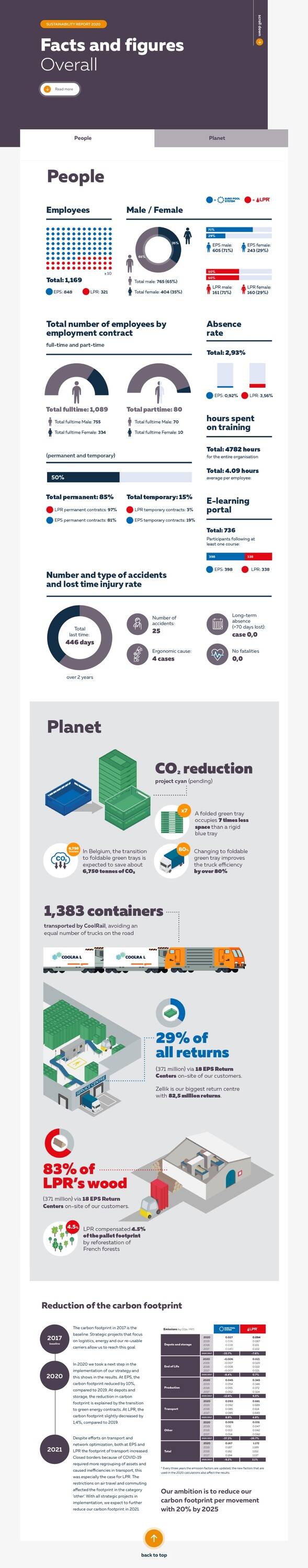

We aim to strengthen and develop teams as well as to have realised a learning and training environment for all employees by 2025

We aim to have a sustainable

employability policy in place for all of our employees by 2025

Further integrate the learning platform with HR system, expand curriculum

Integrate core values in function profiles, leadership, and performance

Management trainings in people management and recruitment

Further reduce repetitive work across regions

Awareness raised on e-learning, new modules developed (including MCV).

Core values used as guidance for performance reviews

Performance reviews integrated in HR system, increased transparency

Repetitive work further reduced; automation continued – especially at new depot

Further implementation of the HR system: e-learning & performance management

Integrating the MCV core values in HR core processes at EPS

Working towards continuous performance management; providing training to support management

Continue reduction of repetitive work across regions

Material

topic

Employee training and

development

Employee health

and safety

People

Goal 2020

Realization 2020

Goal 2021

Goal towards 2025

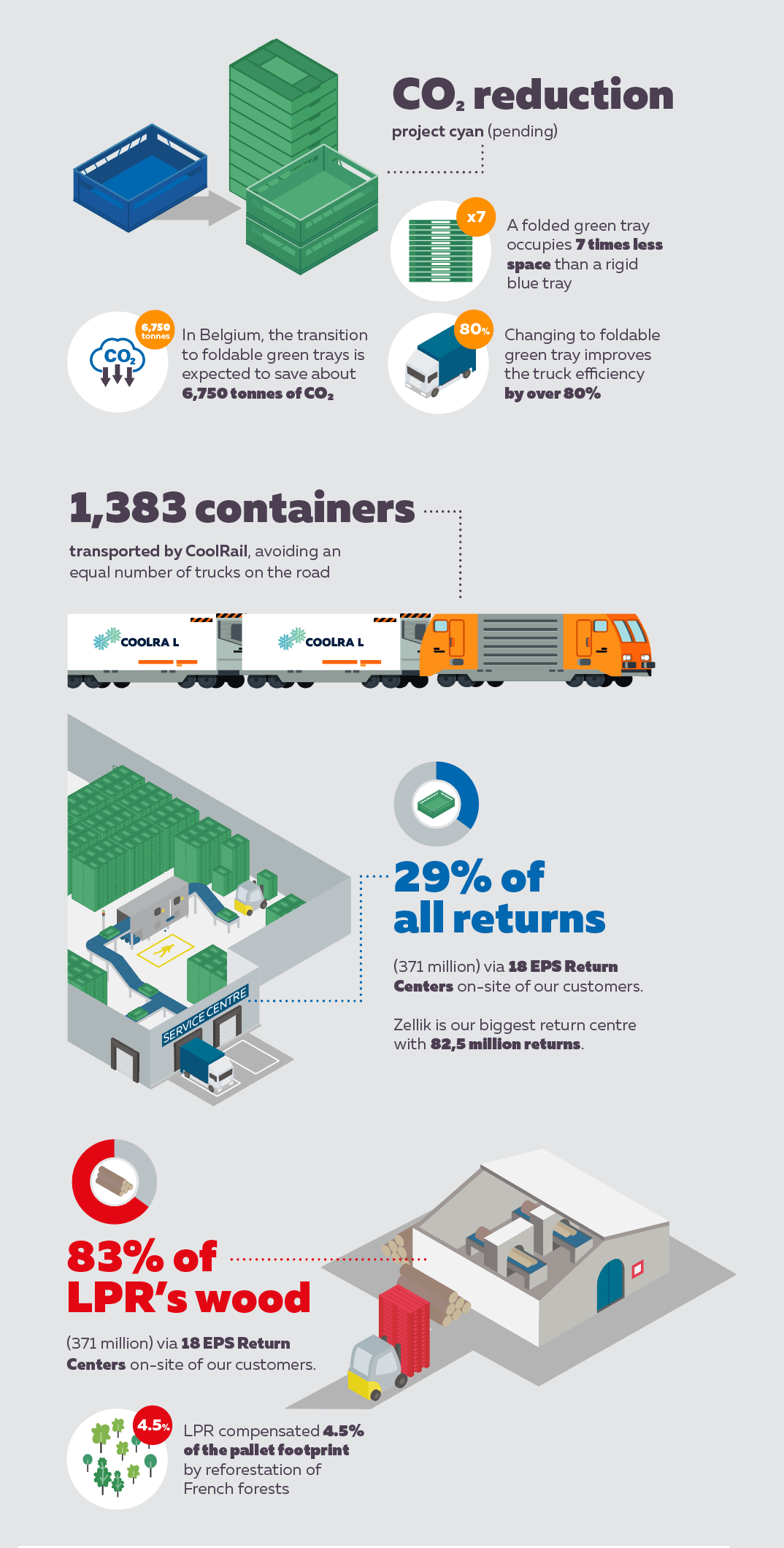

Our aim is to have reduced our carbon footprint by 20% per movement by

2025 (compared to 2017)

By 2025, we will have green energy

contracts at all EPS service centres

By 2025, 5% of our pallet carbon footprint will have been compensated by reforestation

By 2025, all EPS depots uses energy efficient centrifuges

Launch of project Cyan, further optimise transport, towards more multimodal transport

Further expand the capacity of CoolRail to increase rail transport

80% of all EPS depots have green energy contracts

Compensating at least 5% of our pallet footprint by continuing reforestation activities

Continue to replace blowers by energy efficient centrifuges, also at single-line locations

Preparation for the launch of project Cyan; optimisation of transport flows at LPR and EPS

CoolRail operated by Transfesa, expansion of network and frequency of trains.

70% of all EPS depots switched to green energy contracts

5% of the pallet carbon footprint compensated by reforestation

Energy efficient centrifuges installed in Belgium, Denmark and Germany.

Continuing strategic projects to realise reduction in carbon footprint

Further strengthening CoolRail and partnerships

Ensuring that 75% of all EPS depots have green energy contracts

Compensating at least 5% of our pallet footprint by continuing reforestation activities

Further roll-out of energy efficient centrifuges across EPS depots.

Material

topic

Lower carbon

footprint /

sustainable

transport

Energy

efficiency

Planet

Read more

Summary of goals

and results

Planet

People

back to top

Partners

People

Planet

Summary of goals and results